- Home

- News

- News from the South

- Ambition. Dazhi : Local Real Estate Driver-Nanlue Enterprise Co.

Ambition. Dazhi : Local Real Estate Driver-Nanlue Enterprise Co.

Four Local Strengths Increase Investment Efforts

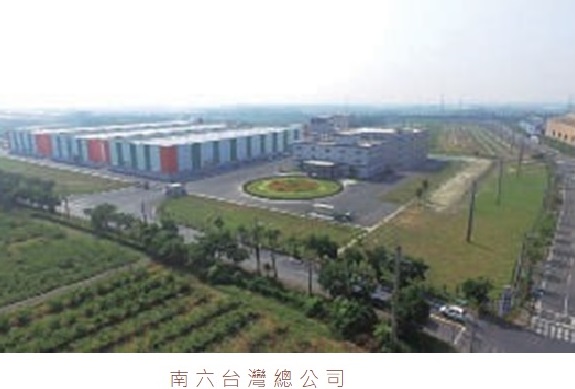

(hereinafter referred to as Nan Liu), based in Kaohsiung and looking to the future, is the largest non-woven fabric manufacturer in Asia.After becoming the national team for masks, the company has been recognized by international manufacturers as the company with the strongest development capability in Asia's non-woven fabric industry. In addition, the company will continue to expand its non-woven fabric industry and invest in a biotech plant in Kaohsiung to expand the field to medical applications, which will be a major contribution to the development of the high tech industry.Injecting new vitality into the Hung Hom industry, highlighting the solid foundation and potential of local developmentThe

Invest in Kaohsiung Seize the Opportunity and Transform and Innovate

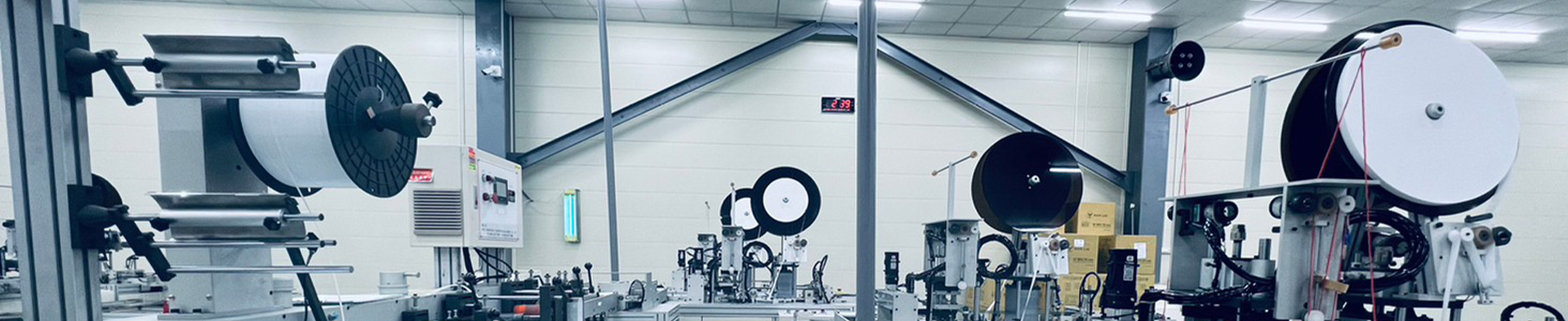

Last year (2019Nan-Li receives approval from the Ministry of Economic Affairs of Taiwan for the "Action Plan to Welcome Taiwanese Businessmen to Invest in Taiwan". Established an operation center and an intelligent production base in Yen Chao District, Kaohsiung City, Taiwan, with a total investment of NT$1,000,000 (US$1,000,000).35This is a billion dollars. This A plan to expand investment in Kaohsiung will also join hands with international enterprises to invest in the development and production of medical-grade non-woven fabrics, and Nan Liu will not only play the role of theIn the future, we will also propose further cooperation and development of technological products. As early as last year, the official opening of theThe first new factory in Yan Chao, new cotton non-woven fabrics, high-speed water-needle fabrics and so on. 2One of the production lines has successfully passed the customer's verification and started to ship products at the end of last year. In the future, if the new Yen Chao plant is fully operational, it is estimated that it can contribute40until50Billion dollars in output value, .This also means that the South Sixth Investment Program in Kaohsiung will soon enrich Kaohsiung's industrial energy.The

"Seizing the opportunity" has always been the management principle of Chairman Huang Ching-shan, who has led Nanlu's many transformations and innovations. The successful transformation and upgrading of a traditional industry and its strong competitiveness can be seen in the growth trajectory of Nanliu, which was founded in 1978 with a $30,000 subsidy from his father, and which originally produced and sold aluminum foil mats for gas stoves, but later switched to sewing and tying zucchini cloth. At that time, Huang rode a vintage motorcycle along the streets to sell rags, and his footsteps spread all over Taiwan, also laying the foundation for the Nan Liu brand. Years later, Nan Liu became Taiwan's largest manufacturer of cucumber cloth, and later developed women's underwear linings, industrial grade polishing and grinding wheels, and began to enter the export market. Huang Ching-shan did not rest on his laurels, but turned to research and development of the upstream raw material of rapes melon cloth - non-woven fabrics, and boldly invested in the addition of production equipment, in an attempt to compete in the price cuts from the low profit margins to seize the opportunity to enter the market early!

"I used to be laughed at by the industry," Huang said, adding that when he bought his first six-meter-two non-woven fabric machine, the industry did not look favorably on it, but when he bought his second one, it was praised by the industry.Namlok boldly invested in the completely unfamiliar field of non-woven fabrics, and with the results so farIt seems to be a pretty clear-cut choice.

Nanliu so from the thin profits of low-end products to higher gross profit items, from diapers, sanitary cotton surface hygiene materials, masks, wet wipes, dust-free high-end wipes, and later pulled up to the medical level, the establishment of the world's most advanced surgical materials key manufacturing technology. The annual production of water-needled non-woven fabrics is the world's largest, and the annual production of water-needled wood-pulp composite fabrics for medical use is also the world's largest. Even at the time of this year's severe epidemic, the company immediately invested in the production of masks without saying a word, becoming the national team of masks that protects the health of the people of Taiwan. For the leader of a large enterprise to enter a completely unfamiliar field, what are the considerations? Huang Qingshan believes that it is important to grasp the opportunity, and then late to be other people to catch up, he said, "Each product has a life cycle of about 10 years. About 3, 4 years climbed to the peak of profitability, it is necessary to think about the next new product, and then spend 2, 3 years of research and development, the introduction of new products in the production line! Constantly innovating and grasping the opportunities have become the driving force behind Nan Liu's continuous growth, and also the advantage of maintaining long-term competition in the rapidly changing external environment.

Industry-University Collaboration to Cultivate Local High-end Talents in Response to Industry Needs

Courage to innovate and grasp the opportunity and good quality, such as laying the competitiveness of the company's own, and then is how to expand outward. In addition to technology and innovation, "cultivating talents" is also one of the keys to expanding the territory. One of the keys to the high quality of Nanliu's products is the reuse of Taiwanese talent. Huang Qingshan said, "Our goal is to do good quality and meet the needs of consumers products," although this sentence is the goal of many several industries, but really achieve a few? Nanliu on the realization of the! Due to the large production capacity, and must be both customized specifications; but also to have a dedicated person to maintain the yield to ensure product quality, talent cultivation will be even more important, so the South of six special network of Taiwan s local schools graduated engineers to form a team, reuse of Taiwanese talent, because the enterprise to deepen the development of the local talent for the transformation and upgrading of production technology is very important, in addition to the communication of obstacles to the company's requirements are quicker to understand, adapt to changes. In addition to communication, local talents are very important for the transformation and upgrading of production technology. In addition to communication, they are also more capable of understanding, responding to, and fulfilling the company's requirements quickly, which not only enables them to be rooted in training, but also reduces the exodus of local professionals in the future, and at the same time creates local employment opportunities. However, the expansion of the territory also needs to be adapted to the local conditions. With the expansion of Nanliu's overseas factories, the company has also cultivated engineers of Indian and Vietnamese nationality locally. In response to the future development of the industry and the needs of the new Yanshao plant, Nanliu has also signed a cooperative agreement with Kaohsiung Medical University (KMU). Kaohsiung Medical University is a major town of medical education and healthcare in Southern Taiwan. The two sides will combine R&D and manufacturing processes to jointly develop beauty, health, and biotechnology products and cultivate high-level biotechnology specialists, in addition to creating employment opportunities for students, and cultivating future professionals in the field of biotechnology for enterprises.

With the rapid evolution of the times, traditional industries are also facing labor shortages and the impact of automation, and in order to take care of "products that are not only good, but also inexpensive," it is necessary to keep up with the pace of the times. Huang Ching-shan has been operating in the traditional industry for a long time, and has come into contact with many employees and readers. He believes that the personnel trained by technical education in the past are relatively stable in terms of skills and work attitude, and that if they rely only on manpower to put in production, their productivity will be much worse than in the past, and therefore, automation of the production process and AI have become a necessary path for the survival and development of the traditional manufacturing industry in the future. Kaohsiung has two ports, one at sea and one at air, with convenient domestic and international transportation; the cost of land and manpower is lower than that of the central and northern parts of the country; there are many universities in Kaohsiung to provide professional talents; and the local government has provided policy support. Nanliu has become an important non-woven factory in the world after years of hard work, which is a good example of how to set a foothold in Kaohsiung and look at the world. In addition to the four advantages of local investment, Mr. Huang believes that it is important for enterprises to uphold the belief of "the cycle of goodness" in order to operate sustainably! This belief has been demonstrated during this epidemic. "When our country needs our help, we will do our best. After all, the government has helped us a lot and is our backbone. With regard to the overall layout of Taiwan's industries in the future, Huang Ching-shan believes that the ASEAN region is an important market. In addition, as the world continues to face the trend of aging, the demand for beauty and health care products is bound to increase, so healthy diet and biotechnology products will become a key focus in the future. In addition, as the economy develops, more and more people are inclined to use more convenient and quicker disposable sanitary products, what will be the trend of the disposable sanitary industry in the future? Huang Ching-shan pointed out that with the rapid growth of Southeast Asian countries, the use of these daily necessities and hygiene products is also growing, and people will further seek more convenient and high-quality products, so non-woven materials also need to be upgraded. In particular, disposable sanitary materials such as diapers and wipes will take up a large proportion of the market. Optimistic about the future prospects of Kaohsiung's industrial and economic development, Huang Ching-shan has taken action to support the investment, and hopes that continued investment can drive the transformation and development of industries, attract more domestic and foreign manufacturers and R & D units based in Kaohsiung, and work together to create continuous innovation, breakthroughs in the solid industrial momentum.

Source : The Hong Kong Institute of Certified Public Accountants (HKICPA)Kaohsiung Economic Development Bureau / Ambition Magazine